Selecting the right pressure relief valve is crucial for protecting equipment and personnel. Moreover, proper valve selection directly impacts operational efficiency and regulatory compliance. This guide explores essential factors that ensure optimal safety and performance in industrial applications.

Understanding Pressure Relief Valves

Pressure relief valves serve as critical safety devices in pressurized systems. They automatically release excess pressure to prevent catastrophic failures. Furthermore, these valves protect against equipment damage and potential injury.

Industrial facilities rely on these devices daily. Therefore, understanding their function becomes essential for operations teams. The valve opens when pressure exceeds predetermined limits, then closes after normalizing conditions.

Types of Pressure Relief Valves

Different applications require specific valve configurations. Consequently, engineers must understand available options before making selections.

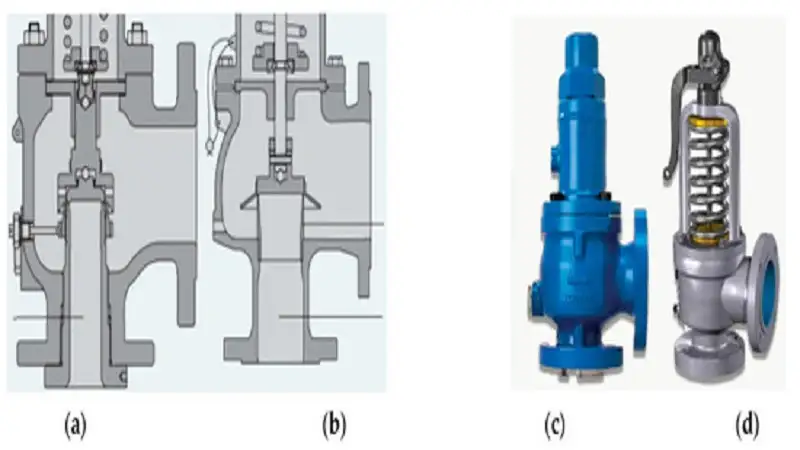

Spring-loaded valves represent the most common type. They use mechanical springs to control opening pressure. Additionally, these valves offer reliable performance across various industries.

Pilot-operated valves handle higher capacities efficiently. They maintain tight sealing until activation occurs. Moreover, these valves excel in systems requiring precise pressure control.

Balanced bellows valves compensate for backpressure effects. They perform consistently regardless of downstream conditions. Thus, they suit applications with variable backpressure.

Choosing a Trusted Pressure Relief Valve Supplier

When sourcing reliable components for your pressure management system, partnering with experienced suppliers makes all the difference. Valves Online offers an extensive range of high-quality pressure relief valve options designed to meet diverse industrial requirements. Their selection includes various types, materials, and capacities suitable for applications across multiple industries.

Furthermore, their technical expertise helps engineers identify the most appropriate valve for specific operating conditions. Additionally, they provide comprehensive product documentation and certification to ensure regulatory compliance. Whether you need standard spring-loaded valves or specialized pilot-operated designs, working with knowledgeable suppliers streamlines the selection process.

Moreover, access to genuine manufacturer products guarantees performance reliability and longevity. Consequently, choosing the right supplier proves just as important as selecting the right valve itself.

Critical Selection Factors

Multiple variables influence proper valve selection. Each factor requires careful evaluation to ensure optimal performance.

Operating Pressure and Temperature

System operating pressure determines valve set point requirements. Engineers must account for maximum allowable working pressure. Furthermore, temperature affects material selection and valve capacity.

High-temperature applications demand specialized materials. These materials maintain integrity under extreme conditions. Consequently, stainless steel and exotic alloys become necessary choices.

Fluid Characteristics

The media flowing through systems significantly impacts valve selection. Liquid, gas, and steam applications each require different considerations.

Corrosive fluids necessitate resistant materials. Chemical compatibility prevents premature failure and leaks. Therefore, material selection directly affects valve longevity.

Viscous fluids may require larger orifice sizes. They flow differently than low-viscosity media. Additionally, suspended solids can cause valve malfunction.

Flow Capacity Requirements

Accurate capacity calculations ensure adequate protection. Undersized valves cannot handle relief scenarios effectively. Conversely, oversized valves may chatter or leak.

Engineers use established formulas for capacity determination. API standards provide calculation methodologies. Moreover, manufacturers offer sizing software for precise results.

Material Selection Considerations

Valve body materials must withstand operating conditions. Carbon steel suits many standard applications. However, corrosive environments require upgraded materials.

Stainless steel offers excellent corrosion resistance. It handles aggressive chemicals effectively. Furthermore, various grades accommodate different service conditions.

Trim materials affect sealing performance. Soft seats provide a tight shutoff initially. Meanwhile, metal seats offer durability in high-temperature service.

Industry Standards and Codes

Regulatory compliance ensures safety and legal operation. Various codes govern pressure relief valve applications.

ASME Code Requirements

The ASME Boiler and Pressure Vessel Code establishes fundamental requirements. Section VIII covers unfired pressure vessels. Additionally, Section I addresses fired boilers.

These standards specify design, manufacturing, and testing criteria. Compliance ensures equipment meets minimum safety requirements. Therefore, certified valves become mandatory in many jurisdictions.

API Standards

The American Petroleum Institute publishes industry-specific standards. API 520 covers sizing and selection methodology. Meanwhile, API 527 addresses seat tightness requirements.

Following these standards promotes consistent industry practices. They help engineers make informed decisions. Moreover, adherence reduces liability concerns.

Installation and Maintenance Practices

Proper installation maximizes valve performance and reliability. Location affects accessibility and functionality. Therefore, planning proves essential before installation.

Valves should mount vertically whenever possible. This orientation ensures proper operation. Furthermore, adequate clearance facilitates future maintenance activities.

Regular testing verifies continued functionality. Many jurisdictions mandate periodic inspections. Consequently, maintenance schedules must align with regulatory requirements.

Common Selection Mistakes

Several errors frequently occur during valve selection. Awareness helps prevent costly mistakes.

Ignoring backpressure effects causes performance issues. Excessive backpressure affects valve capacity. Thus, engineers must calculate total system backpressure.

Neglecting temperature effects leads to premature failures. Materials behave differently at elevated temperatures. Therefore, derating factors become necessary.

Overlooking maintenance accessibility creates operational challenges. Difficult-to-reach valves increase service costs. Additionally, they may receive inadequate attention.

Performance Testing and Certification

Manufacturers test valves before shipment. Pop testing verifies set pressure accuracy. Furthermore, seat tightness testing ensures proper sealing.

Third-party certification provides additional assurance. National Board stamps indicate code compliance. Moreover, certified valves simplify inspection processes.

Documentation proves essential for regulatory compliance. Test reports demonstrate valve capabilities. Therefore, maintaining records becomes critically important.

Economic Considerations

Initial cost represents just one selection factor. Total cost of ownership includes maintenance and downtime. Consequently, quality often proves more economical long-term.

Premium materials increase upfront investment. However, they extend service life significantly. Moreover, reduced maintenance frequency offsets higher costs.

Future-Proofing Your Selection

Anticipating future changes helps avoid premature obsolescence. System modifications may alter relief requirements. Therefore, some design margin proves beneficial.

Modular designs facilitate future upgrades. They accommodate changing process conditions. Additionally, standardization simplifies spare parts management.

Conclusion

Selecting appropriate pressure relief valves requires comprehensive evaluation. Multiple factors interact to determine optimal choices. Furthermore, proper selection ensures long-term safety and performance.

Engineers must balance technical requirements with practical considerations. Standards compliance remains non-negotiable. Meanwhile, economic factors influence final decisions.

Investing time in proper selection prevents future problems. Adequate protection safeguards equipment and personnel. Therefore, thoughtful valve selection ultimately proves invaluable for industrial operations.